Intech’s own fully automated MDI production line is comprised of state of the art production machineries from Switzerland, UK, and Italy. The entire line is under pressure during the production cycle. The medicine is produced using full cGMP standards, filling medical grade aluminum cans to make high quality Metered Dose Inhalers. The automated checkweigher system ensures each can is checked while printing a unique 2D code on the bottom of each can to help identify each can and its contents.

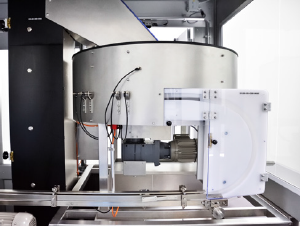

MDI Fully Automated Mixing Line:

The explosion proof mixing tank was built to the ASME-BPE standard in Italy. The tank helps seal the API in the pressurized loop while eliminating the risk of cross-contaminations. A dedicated CIP system helps to clean the mixing system automatically.

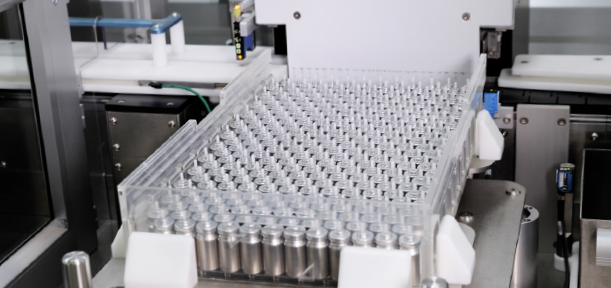

Fully Automated MDI Filling Line:

The MDI filling line employs the worlds most advanced Swiss made automated machine. The entire production line is enclosed during production, while the air supplied is filtered using HEPA filters to ensure clean operations. The filling of the cans are done with extremely high precision at high speed.

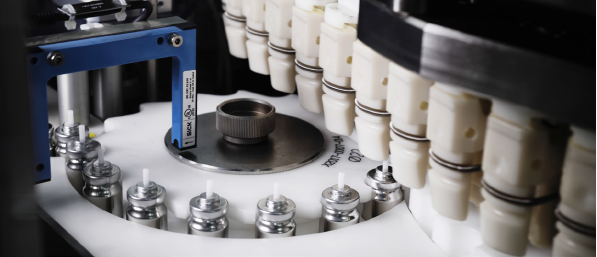

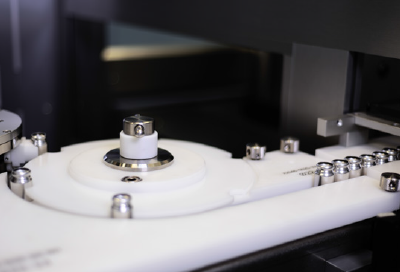

Automated MDI Checkweigher and Stress Test Line:

Each filled cans are tested using our fully automated Stress Test Line. After filling, the cans are weighted and indexed (using printed 2D bar codes) before entering the Stress Test Line. The line has the ability to apply high amount of stress to each individual cans in a safe and efficient way to ensure the integrity of all filled cans.